Radial Lead 3300uf 25v Capacitor

SHDR® Application Notes

1. Polar aluminum electrolytic capacitors are generally polar, and reverse polarity is the cause of short circuit damage and leakage of aluminum electrolytic capacitors. Therefore, it is impossible to identify the polarity on the electrical circuit or use it in a design with polarity change. Please use non-polar electrolytic capacitors when connecting the circuit.

2. Overload Do not apply overvoltage continuously. When the voltage is overloaded, the leakage current of the electrolytic capacitor will increase rapidly, so the working voltage of the electrolytic capacitor should not exceed the rated value.

3. Operating temperature and life The operating temperature of electrolytic capacitors should not exceed the setting range of the maximum operating temperature. The life of electrolytic capacitors depends on the operating temperature. Generally speaking, when the operating temperature of electrolytic capacitors is lowered by 10°C, the lifespan of electrolytic capacitors will be doubled. Therefore, electrolytic capacitors should be used at lower temperatures as much as possible.

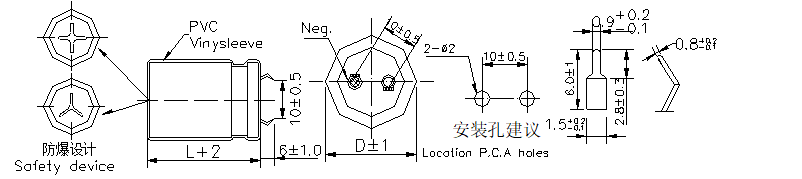

4. Explosion-proof hole For electrolytic capacitors with explosion-proof hole design, one side of the explosion-proof hole should keep a space distance of at least 3 mm from other mechanisms during use. If this condition cannot be met, the explosion-proof hole will not work normally.

5. Ripple current Do not apply a ripple current that exceeds the maximum allowable value of the rated ripple current. The internal temperature of the electrolytic capacitor with excessive ripple current will increase greatly, which will cause the deterioration and damage of the electrical characteristics of the electrolytic capacitor. If it is necessary to apply a ripple current above the rated value, please consult with the manufacturer.

6. Frequent and rapid charging and discharging will cause the internal temperature of the capacitor to rise abnormally, resulting in an increase in leakage current, a decrease in capacity, and sometimes product damage. If you have special requirements for charging and discharging characteristics, please negotiate with the factory personnel .

7. Storage of electrolytic capacitors When electrolytic capacitors are placed for a long time, their leakage current tends to increase. Therefore, before using an electrolytic capacitor that has been placed for a long time, it is necessary to apply a rated voltage to make its electrical characteristics return to normal; if the storage time is longer than 6 months, please connect a 1 kΩ protective resistor in series to make it continue to load the rated value. Operating voltage for 30 minutes. In addition, electrolytic capacitors should be stored in a normal temperature and humidity environment.

8. Inappropriate soldering temperature and time of soldering tin may cause abnormal shrinkage and rupture of the surface hose. Sometimes the high temperature will also conduct heat to the inside of the element through the guide pins and terminals, which will cause adverse effects on the product. Therefore, it is necessary to avoid excessively high temperature and too long. The solder of time.

9. Mechanical strength of guide pins and terminals Do not apply excessive force on the guide pins and terminals. Do not pull the electrolytic capacitors that have been soldered on the PC board, and do not lift or move the entire PC board using the electrolytic capacitors as a force point.

10. Substrate cleaning after soldering If halogenated organic solvent is used to clean the substrate, the solvent may penetrate into the electrolytic capacitor and cause corrosion.

11. Sleeve material The plastic sleeve material generally used is mostly (PVC), if the plastic tube is immersed in xylene or toluene and then placed under high temperature, it will rupture and lose the function of insulation at the same time.

12. The company's product quality is assessed according to the JIS-C-5141W standard, and its reliability test method is based on the standard of JIS-C-5102.

13. According to the Montreal Protocol, the company does not use ozone-depleting drugs in the production process.

Description

1. filter out low frequency interference

2. It is good for high current devices to renew the current, that is, to replenish the instantaneous consumption of energy.

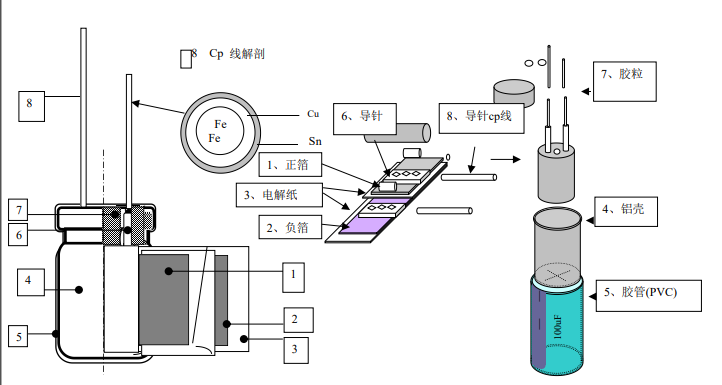

Aluminum electrolytic capacitors are made by inserting a bent aluminum strip as positive* into an aluminum cylinder with liquid electrolyte as the negative*.

The capacitor is called aluminum electrolytic capacitor. It is a kind of general-purpose electrolytic capacitor with good electrical performance, wide range of application and high reliability made of aluminum.

Radial electrolytic capacitors is a general-purpose electrolytic capacitor with good electrical performance, wide application range and high reliability made of aluminum. It is widely used in air conditioners, recorders, washing machines, communication machines and other household appliances, electronic machines, instruments and meters.

Shenghe is a professional manufacturer providing capacitor services, welcome to choose us.

Product Picture

Copyright © Guangzhou Shenghe Electronic Technology Co., Ltd. All Rights Reserved Sitemap | Powered by